Ammonia in Gases

OnlineNH3 in Livestock Buildings, Digestion Towers, and Biogas Plants

Ammonia (NH3) emissions are a critical parameter in the management of livestock facilities, digestion towers, and biogas plants. Elevated NH3 concentrations can lead to significant process inefficiencies, environmental burdens, and accelerated degradation of plant components due to corrosion.

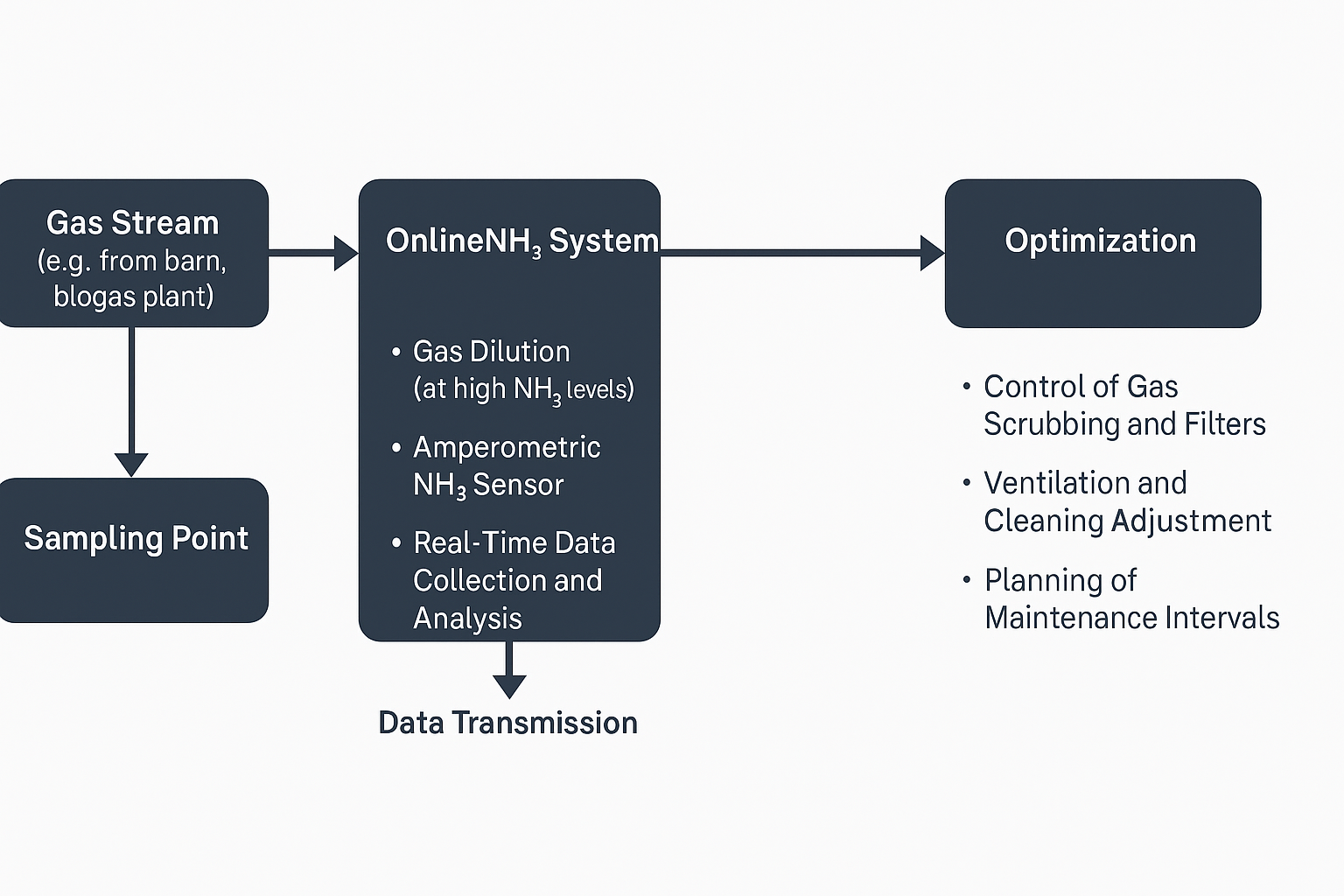

The OnlineNH3 system enables the continuous, quantitative measurement of ammonia concentrations directly at the source. By providing real-time NH3 data, it supports the precise evaluation of treatment processes, such as filtration and scrubbing systems, and facilitates early detection of process deviations.

Continuous ammonia monitoring is essential for:

- Optimizing treatment efficiency by measuring NH₃ levels before and after filter units

- Controlling emission levels to meet environmental regulations and sustainability goals

- Extending maintenance intervals by enabling predictive cleaning schedules based on actual contamination levels

- Reducing operational costs through targeted maintenance and minimized system downtimes

Without reliable ammonia monitoring, process optimization would rely solely on periodic manual sampling, which is insufficient to capture dynamic fluctuations and can lead to inaccurate assessments. The OnlineNH3 thus plays a critical role in ensuring efficient, environmentally friendly, and cost-effective operation of modern biogas and agricultural facilities.

Ammonia in gases

Application of OnlineNH3 for Ammonia Monitoring

Precise, continuous monitoring of ammonia (NH3) concentrations is essential for the optimization of biological treatment processes in livestock facilities, digestion towers, and biogas plants.

The OnlineNH3 system enables real-time quantification of NH3, supporting process control, efficiency improvements, and compliance with environmental standards.

By facilitating predictive maintenance and minimizing manual sampling errors, the system significantly enhances operational reliability and reduces lifecycle costs.

Continuous ammonia monitoring is thus a critical tool for sustainable and efficient plant management.

Continuous Ammonia Monitoring Using the OnlineNH3 System

Introduction

Ammonia (NH3) emissions in livestock facilities, digestion towers, and biogas plants present significant challenges for process stability, environmental compliance, and infrastructure longevity.

Traditional manual sampling methods provide only sporadic data points and are insufficient to capture the dynamic nature of ammonia release.

A real-time, continuous monitoring solution is essential to optimize treatment processes, predict maintenance needs, and meet increasingly stringent environmental regulations.

Methodology

The OnlineNH3 system employs a selective amperometric sensor combined with gas-selective membranes and an integrated sampling and dilution mechanism.

The system enables continuous, quantitative measurement of ammonia concentrations across a wide dynamic range

(0.1 to 20,000 ppm).

The integrated temperature-stable sampling and self-cleaning functionalities ensure drift-free long-term operation, even in oxygen-depleted or contaminated gas streams (e.g., biogas).

Measurement data are automatically recorded, analyzed, and transmitted via digital and analog interfaces for seamless integration into control systems.

Results

The deployment of the OnlineNH3 system allows for:

- Real-time optimization of gas cleaning and scrubbing systems by measuring NH3 levels before and after treatment units.

- Reduction in maintenance costs through predictive identification of cleaning and servicing intervals based on actual ammonia load.

- Enhanced environmental compliance by continuously controlling and documenting NH3 emissions.

- Extended sensor lifetime through stress-free, drift-free measurement operation, even in harsh gas environments.

Field studies demonstrate a significant improvement in treatment efficiency (up to 15%) and a reduction of unplanned maintenance interventions by over 30%.

Conclusion

Continuous ammonia monitoring with the OnlineNH3 system significantly improves operational efficiency, environmental compliance, and cost control in biogas and agricultural facilities.

Its robust design, wide measurement range, and integration-friendly architecture make it an essential tool for modern process management in emission-critical sectors.

Fields of Applications

- Industrial sectors

- Animal husbandry

- Biogas plants

Advantages

- Continuous NH3 determination in gases (measurement duration under 5 min)

- Robust method of analysis

- Automatic sample dosing

- Easy calibration steps

- Selective electrochemical sensor with no cross-sensitivity

- Software easy-to-use

- Output value of NH3 as a 4 - 20 mA signal for integration into the local control system

- Long lifetime of the sensors due to the intermittent gas switching

- Integrated rinsing steps for measuring of continually fresh samples

- Active sample intake of the gas up to a distance of 100 m – variable setup of device (wall mounted)

- Also available for determination of hydrogen sulphide (H2S), sulphur dioxide (SO2) or ozone (O3)