Aquamax KF Online

Reliable Moisture Analysis for Oils and Viscous Substances

Product description

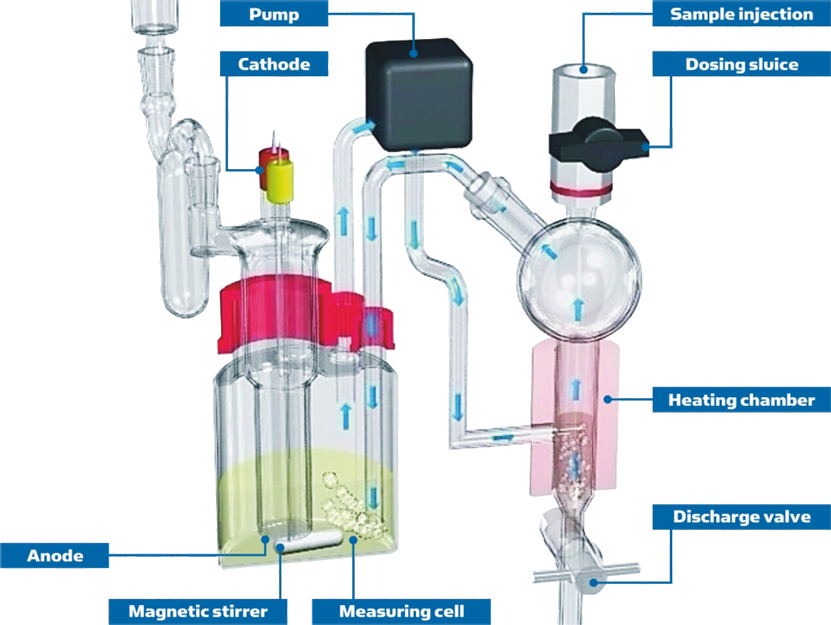

Gas extraction is the ideal method for detecting moisture in oil samples and viscous materials.

The Aquamax KF Online is perfectly suited for continuous water content analysis in oil samples.

Trace levels of water can be measured precisely using a specialized heating chamber designed for oils. Since the sample has no direct contact with the reagent, reagent consumption remains low while detection sensitivity stays high.

The oil sample is automatically transferred from the sampling point of the running process via a pump module and injected directly into the heating oven without any contamination.

Sample volumes from 0.01 mL up to 20 mL can be used, depending on the water content.

Heating can be performed using either a temperature program or isothermal heating.

Moisture measurement takes place in the measuring cell using the Karl Fischer titration method. After the analysis, the oil sample can either be discharged through a valve or returned to the running process.

Closed-Loop Carrier Gas System for Maximum Efficiency

Thanks to the closed-loop carrier gas circulation, additional gas drying is no longer necessary: the carrier gas is continually titrated to complete dryness within the system.

This ensures maximum moisture desorption from the sample while allowing sensitive samples to be heated gently, minimizing degradation and side reactions.

Aquamax KF Online for online water determination

Applications

- Transformer oil regeneration

- Oil treatment plant

- Refineries

- Pipelines

- Crude petroleum monitoring

Advantages

- Closed-loop carrier gas circulation

- No contact of sample with the reagent

- Low consumption of reagent

- Water determination down to 0.1 ppm

- Absolute measurement without calibration or titer determination

- No sample preparation

- For sample amounts from 0.01 up to 20 mL

- Short measuring time

- No blank value, low drift

- Freely selectable heating temperature

- Return of oil sample into system possible

- Applicable for monitoring over long period

Features and Results

The sample ways are coupled directly with monitoring process. Thereby the oil sample is transferred into the Aquamax KF Online without any contamination. The sample transfer can be adjusted to an automatic procedure.

The control system is adjustable for various parameters:

- Delivery rate of dosing pump

- Rinsing steps

- Emptying of oil chamber

Closed-loop carrier gas circulation

Software requirements

Operating system | Windows 10 or higher |

Platform | 32 Bit (x86) |

CPU | 1 Ghz |

RAM | 1 GB |

HDD / SSD | 17 GB |

GPU | DirectX 9 with WDDM 1.0 |

Available languages | German, English |

| PC and Software | Build into the device |

Technical specifications

Device Type | Main unit |

Power supply | 230 V/50 Hz or 110 V/60 Hz |

Dimensions (L x H x D) | 600 x 370 x 720 mm |

Weight | 53 kg |

| Sample administration | Automatically with high resolving ceramic dosing pump |

| Sample amount | 0.01 to 20 mL |

| Heating temperature | 35 to 150 °C |

| Measuring range | over 0.1 ppm |

| Type of result | µg, µg/L, mg/L, mg/kg, ppm, %, by using the formula generator |