Sulfimax GX online GAS

Continuous and Reliable Hydrogen Sulfide Monitoring

Product description

The Sulfimax GX online GAS was developed for the continuous and precise determination of hydrogen sulfide (H2S) in gas mixtures.

The system is engineered to measure both very high H2S concentrations (100 to 20,000 ppm) and low concentrations near the odor threshold (0.1 to 100 ppm), using an integrated dilution stage for optimal flexibility.

Equipped with a selective amperometric sensor featuring gas-selective membranes, diaphragm pumps for gas transport and sample aspiration, and an integrated PC, the Sulfimax GX online GAS ensures continuous recording of measurement data, trends, and alarm conditions.

Measurement results are easily transmitted to the control room via digital (alarm) and analog outputs.

Thanks to its automatic purging circuits, the Sulfimax GX online GAS enables drift-free gas analysis, even in oxygen-free gases like biogas. Its gentle operating mode significantly extends sensor service life.

Designed for wall mounting and equipped with purification stages, the Sulfimax GX online GAS also serves as a solid foundation for H2S-adapted control of enrichment gas processes.

Additionally, the device is available for monitoring ammonia (NH3), sulfur dioxide (SO2), or ozone (O3).

Key Features:

- Continuous monitoring of H2S in gas mixtures

- Wide measuring range: 0.1 to 20,000 ppm

- Integrated dilution stage for flexible analysis

- Long sensor lifetime due to gentle operation

- Drift-free measurement in oxygen-free gases

- Digital and analog signal outputs for integration

- Also available for NH3, SO2, and O3 monitoring

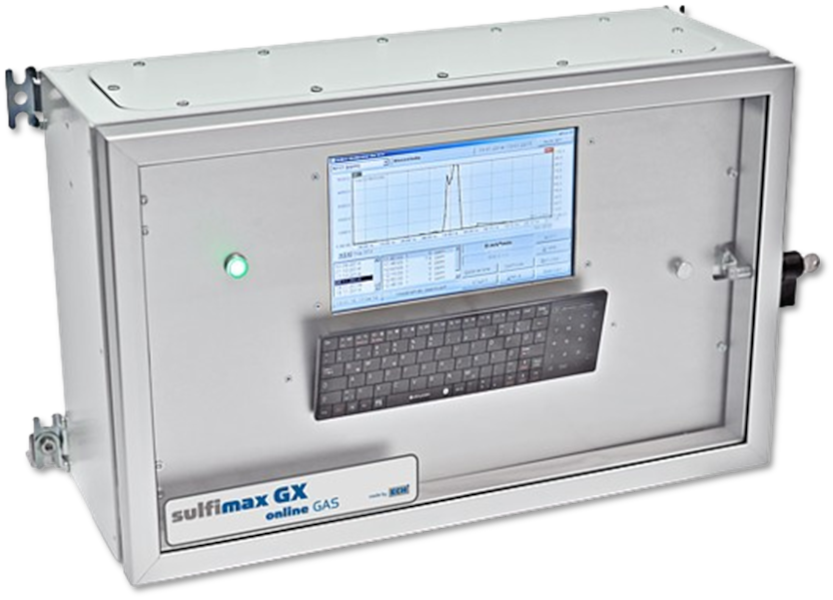

Sulfimax GX online GAS - Automatic analyzer for wall mounting

Applications

- Online recording of the current H2S gas concentration as a basis for H2S-adapted controls (e. g. pump sump, gravity lines, collection tanks)

- Biogas processes, fermentations

- Environment analysis

- Wastewater analysis

- Landfill leachate monitoring

Advantages

- Fully automated sample dosing

- Hardly any cross-sensitivities due to selective electrochemical sensor

- Output 4 to 20 mA for integration of the H2S signal into the local control system

- Long sensor life due to intermittent gas path gas path switching

- Active sample aspiration, thus free installation (wall mounting) with up to 100 m distance from the sampling point

Features and Results

- Continuous H2S gas analysis (measuring time under 5 min)

- Robust analysis method (drift stability)

- Simple calibration

- Simple, clear software

- Integrated purging steps to ensure a constantly updated sample for analysis

- Also available for measuring ammonia (NH3), sulphur dioxide (SO2) or ozone (O3)

Flow diagram of the analysis system

Software requirements

Operating system | Windows 10 or higher |

Platform | 32 Bit (x86) |

CPU | 1 Ghz |

RAM | 1 GB |

HDD | 17 GB |

GPU | DirectX 9 with WDDM 1.0 |

Available languages | German, English |

| PC and Software | Built into the device |

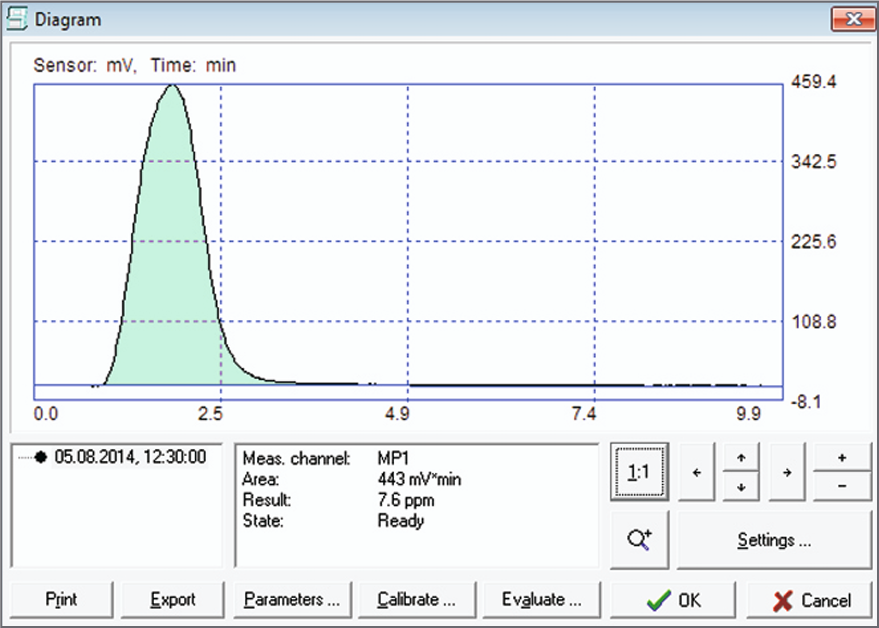

Determination of H2S in gas stream

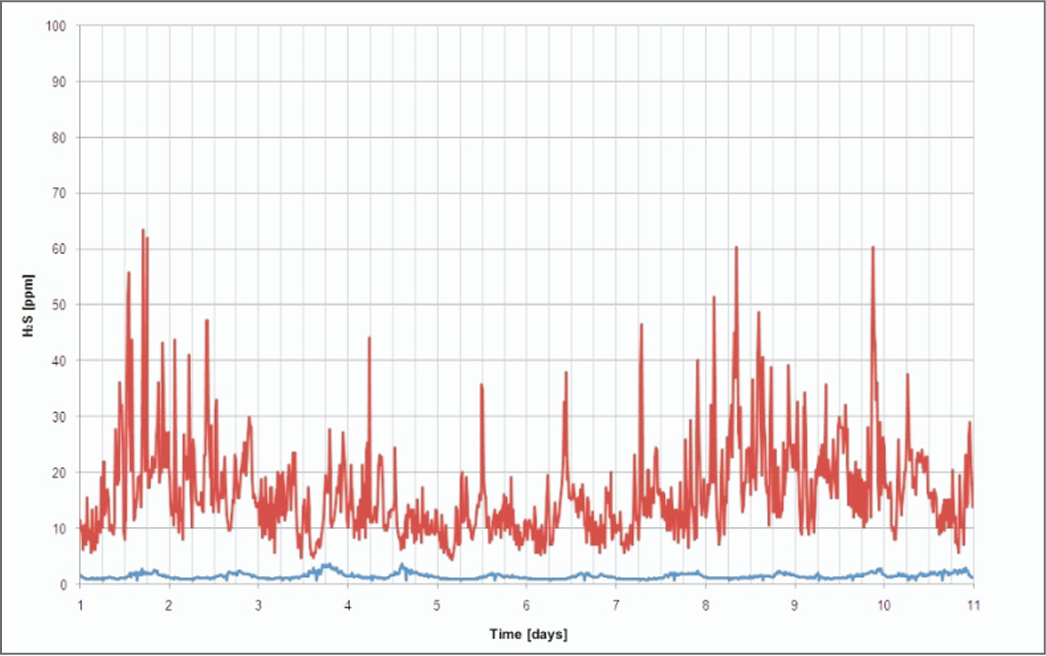

Determination of H2S at two sewage collecting tanks before and after a biofilter

Technical specifications

Device Type | Main unit |

Power supply | 230 V/50 Hz |

Power Input | 100 W |

Dimensions (L x H x D) | 660 x 400 x 250 mm |

Weight | 9 kg |

| Protection type | IP 66 |

| Measuring points | Max. 2 |

| Sampling: | By suction via a transfer line (up to 100 m) |

| Sample volume | 0.1 to 100 mL (depending on application) |

| Sample pressure | Ambient or pressurized |

| Typical measuring time | under 5 min (depending on sample) |

| Measuring range | 0.1 ppm to 20000 ppm (2 %) |

| Gas supply | Internal pump or pressure controller |

| Alarm | Dry contact |

| Signal output | 4 to 20 mA |