Sulfimax GX online WATER ATEX Compliant

Continuous Hydrogen Sulfide Monitoring in Wastewater

Product description

The Sulfimax GX online WATER continuously measures hydrogen sulfide (H2S) and sulfides in wastewater and other aqueous samples with speed and precision.

This enables timely, on-demand interventions in process streams and wastewater treatment procedures.

In its ATEX-compliant version, the analysis system is suitable for operation in potentially explosive environments (ATEX Zone 1 (gas) according to DIN EN IEC 60079-2).

Effective gas extraction ensures complete removal of H2S from the sample, with virtually no interference from the sample matrix. The released H2S gas is directed to a highly sensitive sensor capable of detecting concentrations from 0.01 to 1000 ppm.

Typical measurement times range from 5 to 15 minutes, depending on the sample composition. Even industrial wastewater contaminated with hydrocarbons, ammonia, or highly basic substances can be reliably and reproducibly monitored with the Sulfimax GX Online WATER ATEX.

Sample aspiration, rinsing steps, and the return to the pipe system are all automated. Remote configuration and data access are possible, and measurement results can be transmitted via digital and analog outputs to on-site alarm systems.

Key Features:

- Continuous and precise H2S and sulfide monitoring

- Suitable for wastewater and aqueous samples

- ATEX Zone 1 compliant for explosive environments

- High sensitivity (0.01 to 1000 ppm)

- Automated sample handling and system cleaning

- Remote access for configuration and data reading

- Digital and analog outputs for alarm systems

This Sulfimax GX online WATER fulfils the requirements of the standard ATEX 7733 X

Standard Conformity

The Sulfimax GX online WATER as

ATEX compliant version is suitable

for use in ATEX zone 1 (gas) according

to DIN EN IEC 60079-2.

Applications

- Online acquisition of the current sulphide concentration

-

Environmental analysis, e. g.- Waste water analysis for control systems (pump sump, free level or pressure water pipe)

- Landfill leachate monitoring

- Industrial sewage treatment plants

- Municipal sewage treatment plants

Gas drying

Advantages

- Automatic sample dosing

- Hardly any cross-sensitivities due to indirect method

- Output 4 to 20 mA for integration of the H2S signal into the control system

- Short measuring intervals allow fast reaction to changes

- Low maintenance requirements

Features and Results

- Detection of the true H2S content directly in the liquid phase and thus independent of weather conditions (even in strongly basic samples)

- Simple calibration

- Simple, clear software

- No cross-contamination due to self-cleaning between measurements

- Long sensor life due to integrated regeneration processes

Software requirements

Operating system | Windows 10 or higher |

Platform | 32 Bit (x86) |

CPU | 1 Ghz |

RAM | 1 GB |

HDD | 17 GB |

GPU | DirectX 9 with WDDM 1.0 |

Available languages | German, English |

| PC and Software | Built into the device |

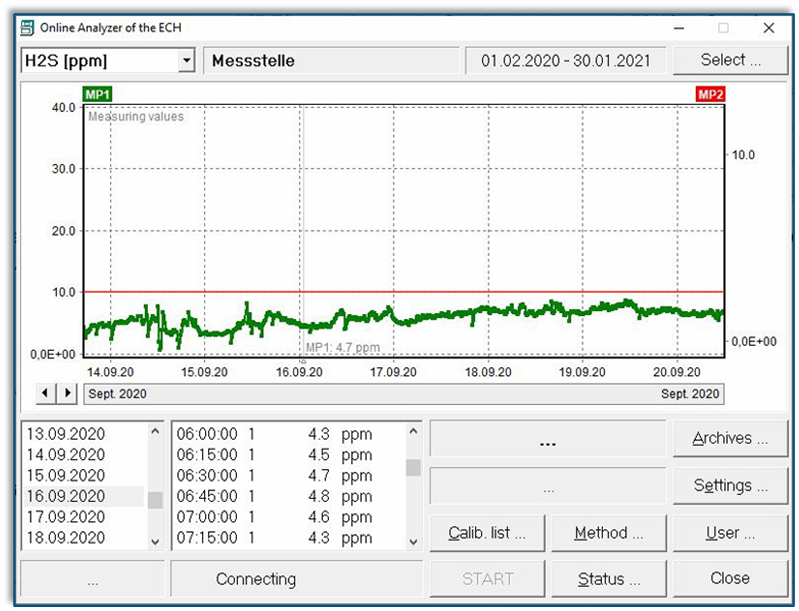

Winter operation with low events

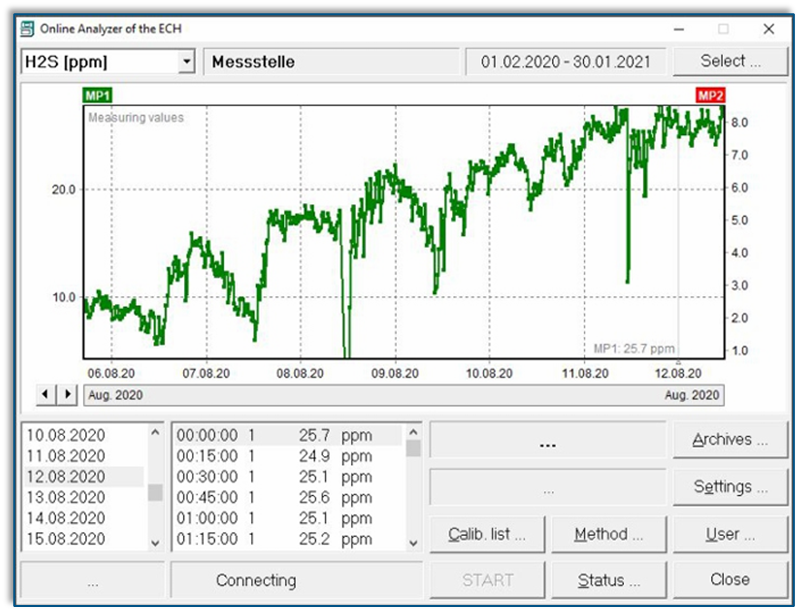

Summer operation with consistently higher but uniform H2S development

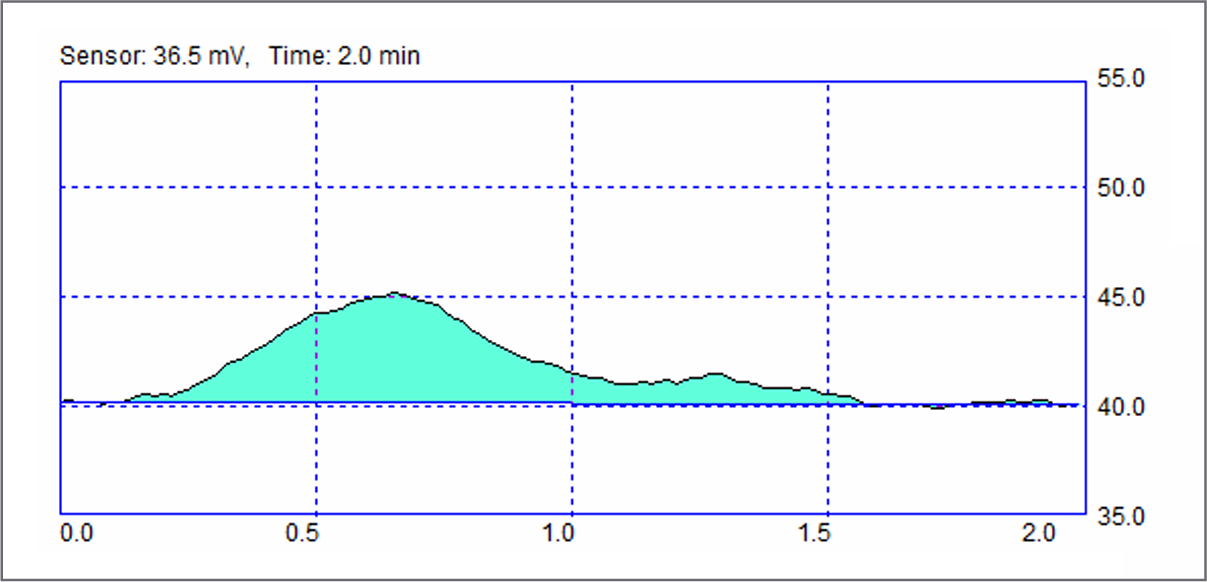

Typical measurement - automatic peak analysis / interpretation

Technical specifications

Device Type | Main unit |

Power supply | 230 V/50 Hz |

Power Input | 250 W |

Dimensions (L x H x D) | 900 x 760 x 315 mm |

Weight | 28 kg |

Protection type | IP65 |

| Sample dosing | Via transfer line (up to 30 m long, from up to 5 m depth) |

| Sample volume | 0.01 to 20 mL |

| Gas supply | Internal pump or compressed air |

| Gas flow | Up to 50 L/h |

| Typical duration | 5 to 15 min (depending on the sample) |

| Range | 0.01 to 1000 ppm |

| Resolution | 0.1 µg abs., output signal linear |